Introduction to Particle Image Velocimetry (PIV)

Muhammad Nadeem, Muhammad Yamin, Muhammad Azhar Ali, Muhammad Mubashir Omar

Faculty of Agricultural Engineering & Technology, University of Agriculture, Faisalabad, Pakistan

Particle Image Velocimetry (PIV) is a non-intrusive laser optical measurement technique used to obtain instantaneous velocity vector in a cross-section of gas or liquid flows. This technique can be used for research and diagnostics into flow, turbulence, microfluidics, spray atomization and combustion processes. This technique can also be used for spray characteristics and to measure the flow rate through sprayer nozzles. Based on optical principles there are different global-wise techniques, mainly include Particle Tracking Velocimetry (PTV), Particle Streak Velocimetry (PSV) and Particle Image Velocimetry (PIV).

The concept of PIV may start from the observation of a person while watching the debris movement on the surface of water for velocity measurement. So, the viewpoint of particle velocimetry is very old and simple but considered as modern technique. PIV means the accurate quantitative measurement of velocity vector of flow for large number of points simultaneously. In 1980s 1st time the term “Practical Image Velocimetry” (PIV) was used in literature, before that people were not familiar with this technique. In last 30 years a lot of progress was done in computer techniques, image recording and evaluation techniques and laser operation that made the PIV very famous measuring tool. PIV techniques can be used to measure the instantaneous turbulent velocity fields. Tracer partials (seeded particles) are used for submerged flow and air flow measurements.

PIV and Tracer particles (Seeded Particles)

Tracer particles are added to the flow and this system is based on the analysis of the position of tracer particles recorded at successive times by a high-resolution camera. The tracer particles should be large enough to damp the Brownian moment. But at the same time tracer particles should be small enough to follow the flow fields without disturbing the flow field. Mostly polystyrene particles are used as tracer particles.

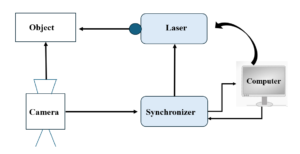

In general, to produce the images, tracer particles are illuminated by pulsed sheets of laser light at precise time intervals that are recorded by using a charge-coupled device (CCD) or complementary metal–oxide–semiconductor (CMOS) camera. A key element in the PIV technique is the analysis of these images to measure the particles displacements. This technique can be used for a variety of research and diagnostics into flows, turbulence, microfluidics, spray atomization and combustion processes.

Standard PIV system

Standard PIV measures two velocity components in a plane using a single CCD (Charge-Coupled Device) camera. The method can measure an entire two-dimensional cross section of the flow field simultaneously. Instead of a two-dimensional field of view, three velocity components can also be measured with the use of second camera and that is called stereoscopic imaging system.

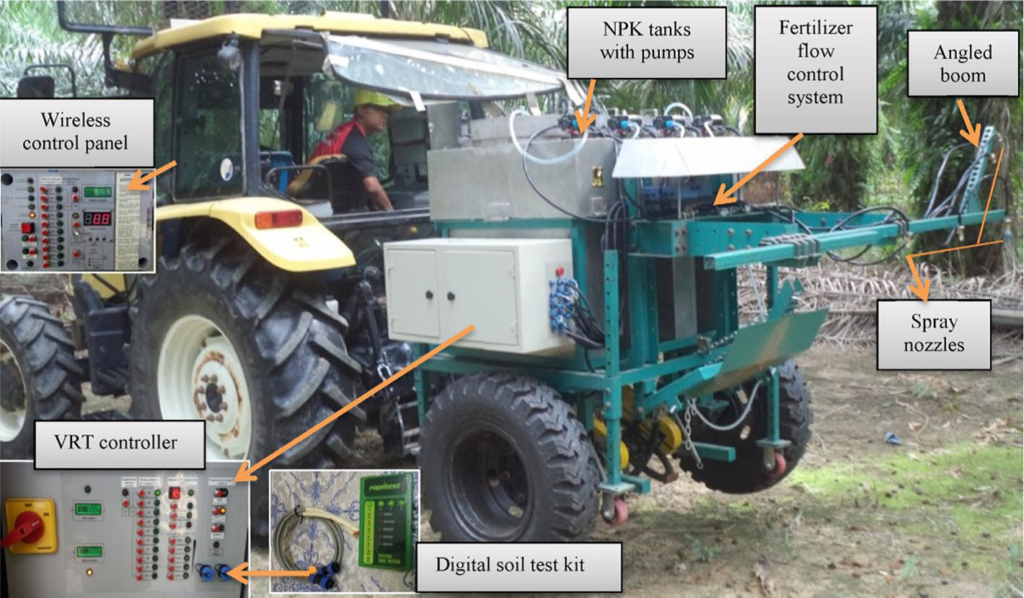

A standard PIV system consists of

1. Multi-pulsed laser system

2. Two or three digital cameras

3. Computer system with synchronizer

A multi-pulsed laser system which synchronized with two or three digital cameras with a computer system to analyze the images obtained from cameras. There are two PIV arrangements one is called 2D-2C PIV while 2nd is called 2D-3C PIV. In 2D-2C arrangement PIV uses one camera while in 2D-2C PIV system uses two cameras. As for volumetric measurements, three cameras will be used, but due to complication of experimental setup and cost of PIV the most common PIV measurement is still 2D-2C PIV.

Application of PIV in Fluid Dynamics

Canals and micro fluids measurement

Many researchers measured the surface velocities in an irrigation canal by using PIV and converted into depth averaged velocities by a log-law curve. They also measured the discharge of irrigation canal by using Parshall flume and PIV methods. The results obtained through Parshall flume and PIV were found with good agreement of 5% difference. The images of tracer particles on the surface of canal water were captured by using Video camera (Speed Dome). This camera was capable of taking 30 frames per second with a camera revolution of 811 × 508 pixels. These results suggested that image measuring techniques can be used to measure the discharge of irrigation canals more precisely without disturbing the canal flow. A few researchers also measured the three-dimensional, three component velocity by using the Micron PIV and PTV (Particle tracking velocimetry).

Co-current liquid-liquid flow

This technique can be used to differnetiate the co-current liquid-liquid flow by using a circular tube. Here is an example of this. The Aliphatic hydrocarbon (Exxsol D80) and aqueous solution of glycerol were used as fluids for these experiments. Graticule technique was used to correct the optical distortion due to circular tube. The concentration of glycerol was so adjusted that both the fluids (glycerol + water) had same refractive indices. The flow was investigated by using the laser optical diagnostic techniques, Planar Laser Induced Fluorescence (PLIF), Particle Image Velocimetry (PIV) and Particle Tracking Velocimetry (PTV). The images data obtained from PLIF was agreed with simple stratified laminar-laminar flow model (predictive model). PIV and PTV techniques were used to investigate the velocity conditions, flow pattern and velocity profile of two different fluids moving in same investigating area. The results of PIV and PTV concluded that, the velocity profile of lower layer of fluid (glycerol/water) more viscous and heavier had characteristics of laminar flow while the characteristics of upper layer of fluid (Exxsol D80) less viscous and lighter had characteristics of turbulent flow.

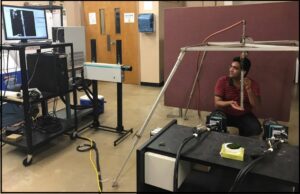

High presseure water mist nozzles

Husted in 2009 evaluated high-pressure water mist nozzles using Particle Image Velocimetry (PIV) and Phase Doppler Anemometer (PDA). Droplet size is one of the biggest problem in fire extinguishing with water mist. A hollow cone nozzle and full nozzle cones were evaluated by using PIV and PDA techniques. PIV system was used to find out the overall spray behavior including spray spread and velocity field while PDA was used to measure the droplet size and flow velocity.

In PIV cross correlation worked well to define the characteristics of spray behavior instead of individual droplets. PIV is suitable for capturing the dynamics of a spray, but PDA can only be used for steady sprays. Based on PDA results it’s concluded that surrounding air (boundary conditions) has a significant effect on the sprayer behavior.